Ihr Partner im Bereich der Industriellen Bauteilreinigung und Automationslösungen.

Das MTM-Portfolio bietet für jede Aufgabenstellung die passende Lösung.

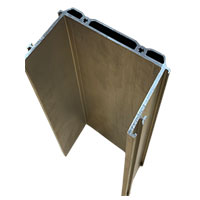

Maschinenbau

Industrielle Reinigungsanlagen und Teilereinigungsanlagen für die Bauteilreinigung im Bereich mechanische Bearbeitung und Fertigung.

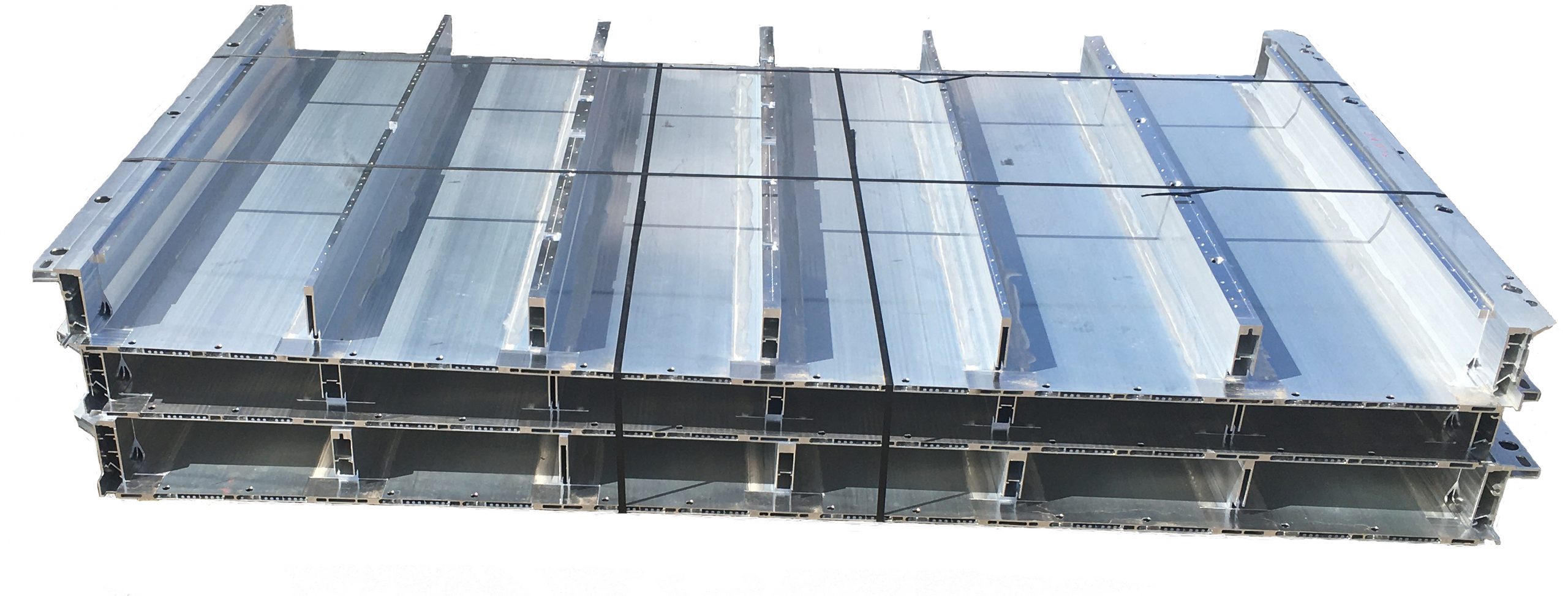

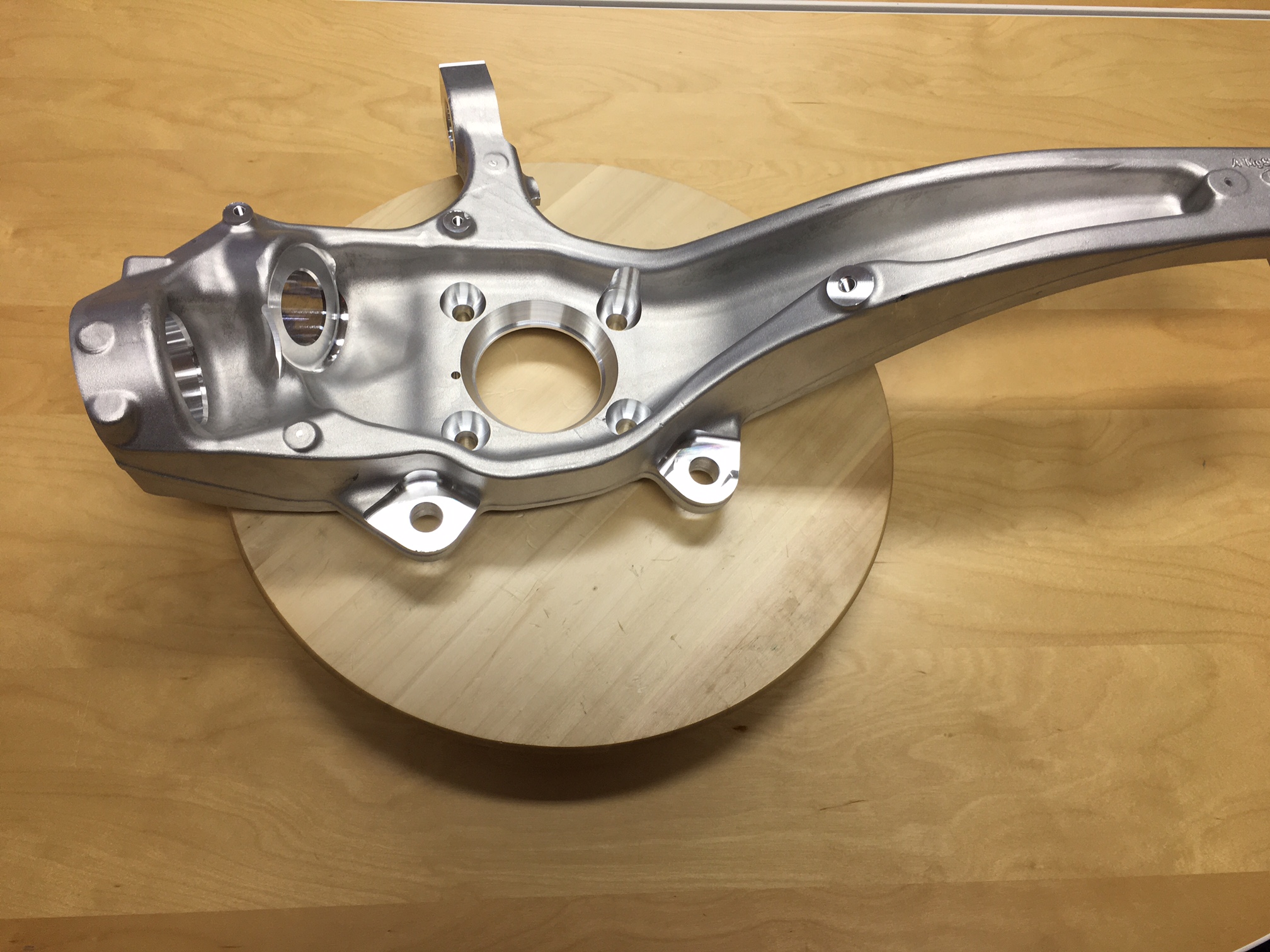

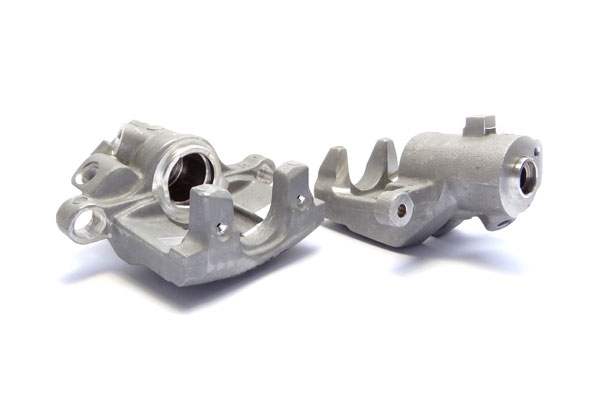

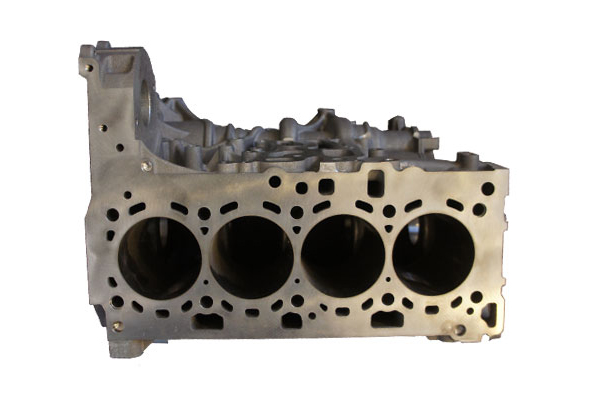

Automobil

Reinigungsanlagen, Bürstentgratanlagen und Hochdruckentgratanlagen für die Teilereinigung im Bereich Powertrain (Elektromotorengehäuse, Zahnräder für Elektromotorendifferential, Statorgehäuse,..) , Engine und Transmission.

Feinstreinigung

Tauchreinigungsanlagen und Ultraschallreinigungsanlagen für die Feinstreinigung z.B. in der Medizintechnik und der optischen Industrie.

Oberflächenbearbeitung

Bandsreinigungsanlagen, Reinigungsanlagen für Maschinenteille für die Aktivierung vor dem Beschichten, Entschichtung und Konditionierung von Oberflächen.

Automationstechnik

Handlingsysteme für Teilereinigungsanlagen, Bearbeitungsanlagen, Mess- und Prüfeinrichtungen, Paletten- und Einzelteilautomation.